By Application

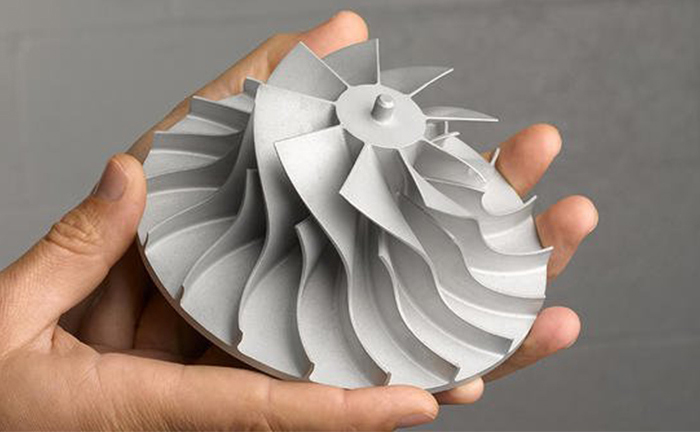

- Casting

-

3D printed casting patterns have enabled the evolution of significantly more timely and cost-efficient production of casted parts. Indirect comparisons between 3D printed casting patterns and traditional methods, customers have saved anywhere from $20,000 to $200,000 per part, and removed weeks and months from the process.

- Injection Molding

-

Injection Molding is a manufacturing process for producing parts in large volume. It is most typically used in mass-production processes. The principal advantage of injection molding is the ability to scale production en masse. Through Injection Molding Reduce mold and tool design times by 75%, Reduce mold production lead times by 80%, Significantly streamline injection mold design and production & Measurably lower production costs with direct metal printing

- Vaccum Casting

-

Vacuum casting is a flexible & formative manufacturing process that provides low volume parts with production level quality. This makes the parts suitable for fit and function testing, marketing purposes, and for creating final parts in limited quantities. Quick turnaround of parts is also achievable with vacuum casting.

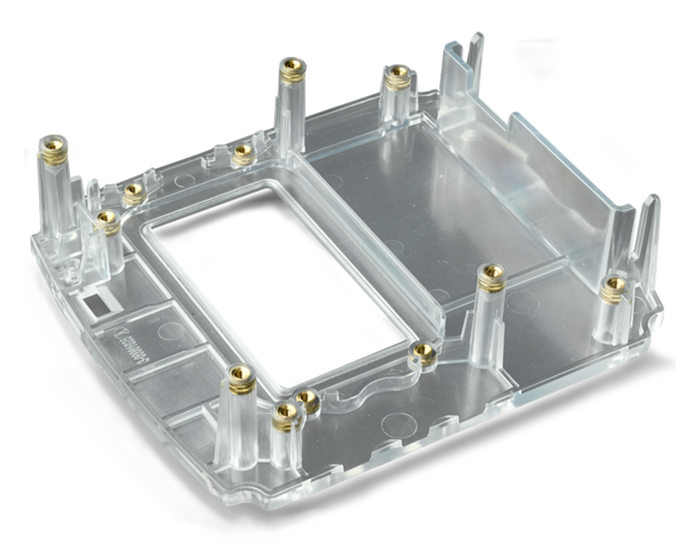

- Jigs & Fixtures

-

Jigs and fixtures are a manufacturing staple that are evolving through additive manufacturing to be more readily available, cost-effective and performance-oriented. The use of 3D printing for jigs and fixtures enables: Faster development and/or production cycles, Reduced investments in time, cost and materials, Improved functionality for workflow and workforce, Enhanced self-sufficiency to own processes and outcomes.

3D printing offers more than a new methodology for producing accurate and high-quality parts for production support: 3D printing enables new design strategies for optimized parts that can reduce machine wear and tear, enhance worker safety, streamline production workflows, and save considerable time and money.

- Rapid Prototyping

-

Rapid prototyping, a methodology for which additive manufacturing was invented, has developed across 30 years to deliver new efficiencies and productivity during the product design and development process. The new additive technologies and materials for prototyping can deliver:

- More than 15 times faster prototyping than alternative methods

- Same day prototype production

- Decreased product time-to-market

- Development of better products, faster

- Reduced costs of product development

- End Use

-

With the incredible advancement in part accuracy, resolution, material strength and variety, and time efficiency, 3D printing for end-use parts is being utilized as the next great revolution in manufacturing. 3D printing not only optimizes processes across the entire manufacturing cycle but also produce accurate end-use parts.

- Healthcare

-

3D printing technology offers design flexibility & exciting new ways to provide personalized care within the medical industry and create better-performing medical devices. Surgical instruments, like forceps, hemostats, scalpel handles and clamps can be produced using 3D printers. Creating personalized surgical instruments provides many benefits including faster and less traumatic procedures, as well as increase a surgeon’s dexterity and support better surgery outcomes.