Aerospace & Defence.

Material Innovations Expands Production Applications.

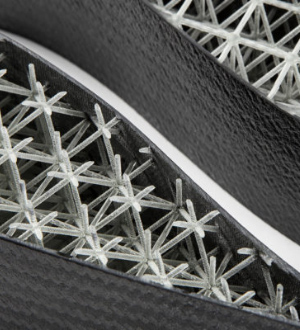

The Aerospace & Defence industry being the early adopter and contributor to the continued development of 3D Printing technologies and materials is a great example of utilization of 3D printing technologies with a clear value proposition as 3D printing allows fabrication of structurally complex design characterized by non-traditional organic shapes that provides high mechanical performance with minimum weight.

Aerospace industry leverages global 3D printing solutions and expertise to deliver manufacturing productivity with lowered fuel costs through light weighting and parts consolidation; innovative 3D printed casting patterns, 3D data recovery, injection-mold design, and direct metal printing of airworthy parts.

Customizable 3D printable designs are vital to achieving greater levels of agility and flexibility within the military. 3D Printing is the ideal solution in Defence industry for creating quick concept models and prototypes, without the need for expensive tooling. Design concepts and validation testing, can be done much faster, thereby shortening the product development cycle.

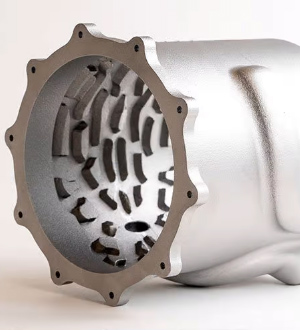

Technologies like Direct Metal Printing (DMP) and Wire Arc Additive Manufacturing (WAAM) are already widely used to repair functional military equipment. Worn out surfaces of turbine blades and other high-end equipment can be restored and repaired using these technologies. As replacement parts can quickly run out of stock, 3D scanning techniques can be used to reverse engineer an available part, which then can be easily replicated via 3D printing.

High-value aerospace & defense applications.

Lightweight cabin components, Brackets.

Propulsion.

Heat Exchangers.

Investment casting patterns.

Electric Engine Components.

Radio Frequency (RF) Passive Hardware.

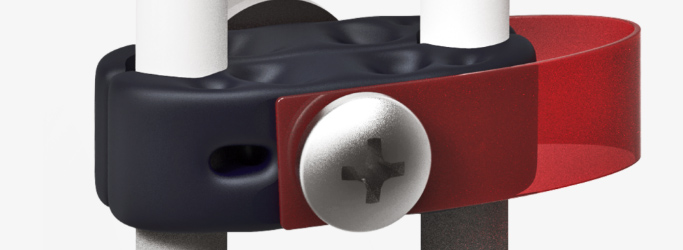

Brackets, harnesses, and sensor mounts.

Precision inspection tooling.

Work holding.

Functional prototypes.

Replacement parts.

Prototypes.

Custom tooling.

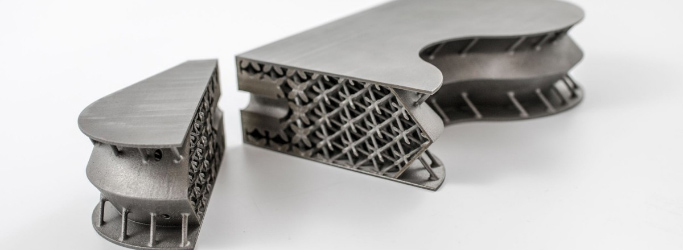

Variable Shelling.

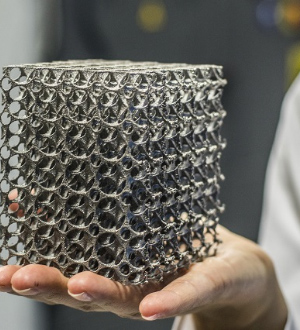

Lattice infills.

High stiffness sandwich structures.

Jigs & Fixtures.

Brackets, harnesses, and sensor mounts.

Titanium Inserts for Spacecraft: 66% Lighter with Metal 3D Printing .

Emirates Uses SLS Printing For Better Fuel Economy and Supply Chain Efficiency .

Thales Alenia Space and 3D Systems Prove Viability of Direct Metal Printing .

ACS Custom Develops, Produces Custom Products in Days with Figure 4 Standalone. .

US Air Force Optimizes CubeSat Using Architected Materials .