Ceramic Stereolithography.

C100 Easy FAB.

Properties

3D Printer for developing & prototyping

Highlights

Free link support technology

User friendly

Stereolithography laser

A pressure tank (1,5 liter) feeding to provide the material quantity required for an optimized run 100*100*150

Peristaltic pump for flowrate control to manage quantity of printed ceramic slurry

Easy scale up to C3600 (600 x 600 x 300 mm)

C100 Easy LAB.

Properties

The freedom to develop your own process

Highlights

Free link support technology

Dedicated to R&D development

User friendly

Stereolithography laser

Start a printing run with only 60 mL of ceramic formulation

Cartridge of 180 mL, 360 mL, 600 mL or 920 mL available)

C3600 Ultimate.

Properties

For mass production of

big parts

Highlights

Industrial 3D printer

Free link support technology

Stereolithography laser

Reduced unit price / parts

Reduced cleaning time

Well adapted to serial printing

Materials offered for Ceramic Stereolithography.

- Oxide Ceramics.

-

Alumina.

Good mechanical behaviour in the high temperatures, good thermal conductivity & high electric resistivity

Zirconia.

Excellent mechanical properties, Chemical inertness & High Hardness

Silicore.

High mechanical resistance, Porous ceramic, good leachability and Very stable at high temperature

Alumina Toughened Zirconia.

Great Hardness and tenacity, Biocompatibility and Resistance to wear and thermal shock

Cordierite.

Low CTE (Coefficient of Thermal Expansion), Low thermal conductivity, Wear Resistant and Good for vacuum application

Zirconia 8Y.

Ionic conductivity, Oxygen-ion conductivity and Heat insulating

TCP.

Biocompatible and Bioresorbable

Silice Si02.

Good leachability

HAP.

Biocompatibility, Excellent bioactivity and Good osseointegration - Non-Oxide Ceramics.

-

Silicon Nitride.

Good resistance to thermal shocks, Good resistance to wear, Mechanical properties, Low wettability against molten metals, Good electrical insulation, Resistance to corrosion (liquid and gas)

Aluminum Nitride.

High thermal conductivity, Electrical insulation and Good mechanical strength

Ceramic Stereolithography.

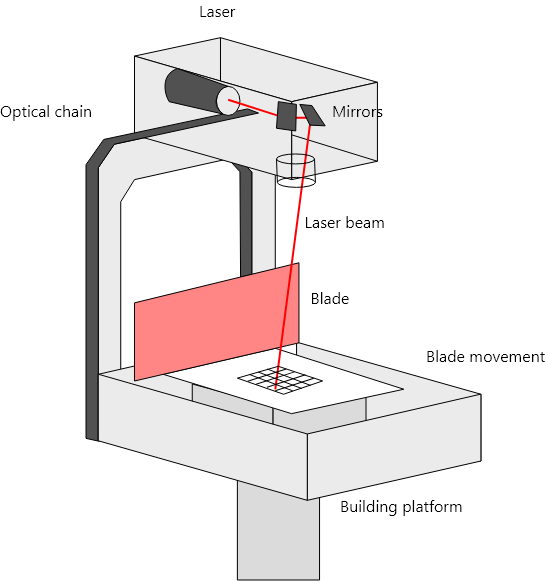

Ceramic additive manufacturing (C-AM) is highlighted as a technology that can overcome the inherent limitations of ceramics such as processability and formability. This process creates a structure by slicing a 3D model and stacking ceramic materials layer-by-layer without mold or machining.

3D Ceram offers a wide range of ready-to-use high strength ceramic pastes and the top-down stereolithography enables technology that can print without supports. The tray moves down as the part itself is built from the bottom-up. 3DCeram is able produce consistent parts with high precision and fine details.

The feeding of the printing material is done by a printing material is fed into a cartridge which is simply filled at the beginning of the printing cycle. It is possible to re-fill the cartridge during the printing cycle.