MultiJet Printing (MJP).

ProJet MJP

2500W Plus.

Properties

Fast and affordable jewelry wax pattern printer

Highlights

Pre-series and series production of jewelry metal pieces

Customized jewelry metal pieces manufacturing

Figurines, replicas, collectibles and art pieces

Software

3D Sprint

3D Connect

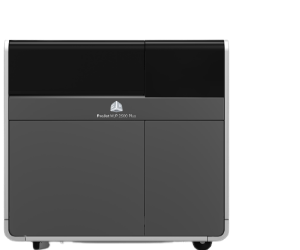

ProJet MJP

2500 IC.

Properties

Tool-less production of 100% wax casting patterns

Highlights

High quality small to mid-sized wax patterns that fit directly into a standard foundry casting process

Ideal for customized metal components, bridge manufacturing and low volume production

VisiJet® M2 ICast 100% wax material delivers the same melt and burn-out characteristics of standard casting waxes

Software

3D Sprint

3D Connect

ProJet MJP

2500/2500 Plus.

Properties

MultiJet Printing Quality, Speed and Ease of Use Made Accessible

Highlights

Up to 3x higher 3D printing speeds than similar class printers and finished part delivery up to 4x faster with 3D Systems MJP EasyClean System

Capable of printing in rigid, engineering-grade, high temperature resistant, elastomeric or biocompatible materials, in clear or in a range of opaque colors

Perfect for concept modeling, rapid design iteration and validation, jigs and fixtures, patterns and molds

Software

3D Sprint

3D Connect

Materials offered for MJP.

- Visi Jet.

-

VisiJet M2 ICast (MJP).

100% wax patterns for industrial investment casting

VisiJet M2 CAST (MJP).

Durable, 100% wax for precision jewelry metal casting patterns

VisiJet M3 CAST (MJP).

Durable, 100% wax for high resolution casting patterns

VisiJet M3 Hi-Cast (MJP).

100% wax for high resolution casting patterns

MultiJet Printing (MJP).

MultiJet Printing (MJP) is a material jetting printing process that uses piezo printhead technology to deposit materials layer-by-layer. These high-resolution 3D printers use a separate, meltable or dissolvable support material that can be completely removed in a virtually hands-free process, allowing even the most delicate and complex features to be thoroughly cleaned without damage.

MJP professional 3D printers offer integrated solutions of hardware, software, and materials, that deliver true-to-CAD accuracy with fast print speeds, easy operation, and hands-free post-processing for high productivity and true simplicity, from file to finished part. These office compatible printers provide convenient and affordable access to high-quality printed parts.