Dental.

Material Innovations Expands Production Applications.

As with other professional sectors of the economy, dentistry is rapidly transitioning to a digitized business model and the evolution of 3D printing in dentistry and orthodontics is certainly understandable. Soon, it is likely that digital scanners and 3D printers will become just as indispensable to dental professionals as the equipment they’ve traditionally used.

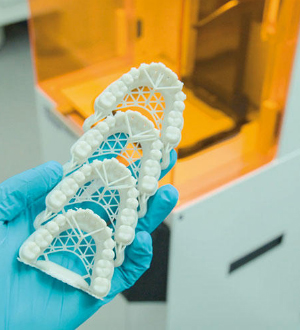

Orthodontics already uses popular AM processes like vat polymerization, material jetting and material extrusion (fused filament deposition). 3D printing in dentistry will improve results for patients while simultaneously shifting production from overseas dental labs back to local facilities.

Dentistry requires customized crowns, implants, dentures and appliances, and 3D printing’s strength lies in the production of high-resolution, one-of-a-kind objects. Digital scanning combined with 3D printing, promises to reduce the anxiety associated with the dental experience.

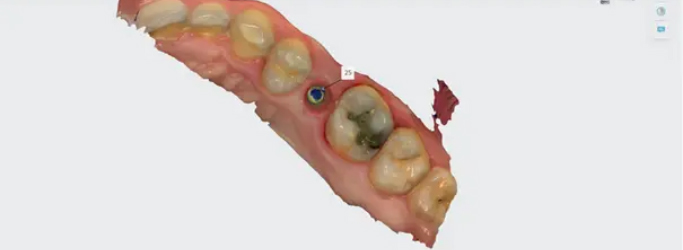

Now, it is possible to take a contactless 3D scan of a patient’s mouth as a prelude to crown, bridge and denture fabrication. Dental clinics with on-site 3D printers are well-positioned to provide dental solutions to their patients in minutes or hours rather than days or weeks.

3D printing has always been present in the dental industry as one of the more significant processes technicians use and is also poised to take on serious reconstructive challenges. It is now possible to use 3D printing in mandibular reconstruction and lower arch implant rehabilitation.

High-value dental applications.

Prosthodontics.

Orthodontics.

Implantology.

Upper full arch rehabilitation using 3D printed temporary restorations .

Full-coverage crown restorations on seven maxillary teeth and six mandibular teeth .

Implant restoration of #25 using digital workflow and surgical guide .

Hybrid Technologies Grows Business with Full-Arch Palatal Jigs 3D Printed on NextDent 5100 .