Software.

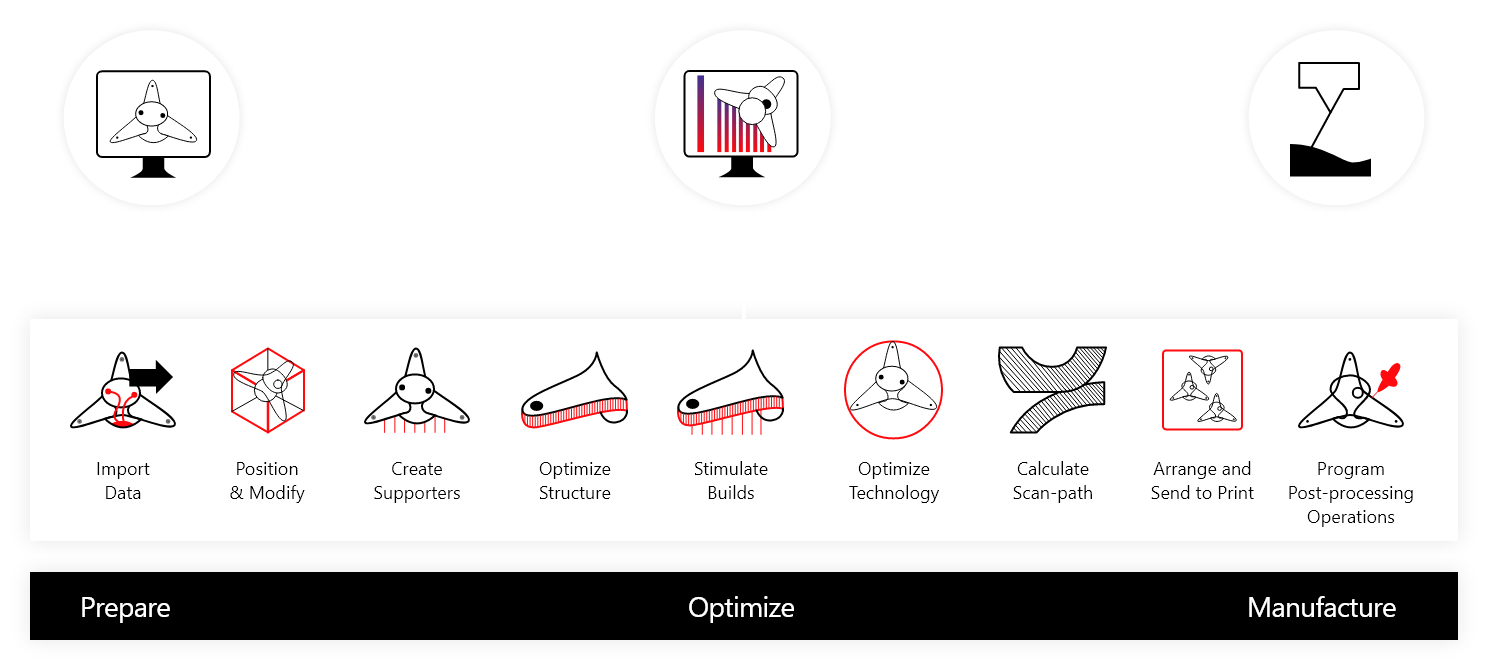

Additive manufacturing software enables successful 3D printing by taking CAD data and preparing and optimizing that data for a 3D printing process. The preparation process includes optimization techniques, building proper supports to prevent build failures, simulations of build methods, establishing the printing strategies, calculation of scan-paths, arranging the final build, and sending to print.

AM software provides data on the most efficient design methods for a given product and resources. AM software requires this level of data analyzation due to the different ways that AM processes handle materials.

Shree Rapid Technologies (SRT) offers top-of-the range software for the additive manufacturing industry from brands like 3D Systems, ZEISS, GOM, Materialise and more.

-

Reverse Engineering /Manufacturing Applications

-

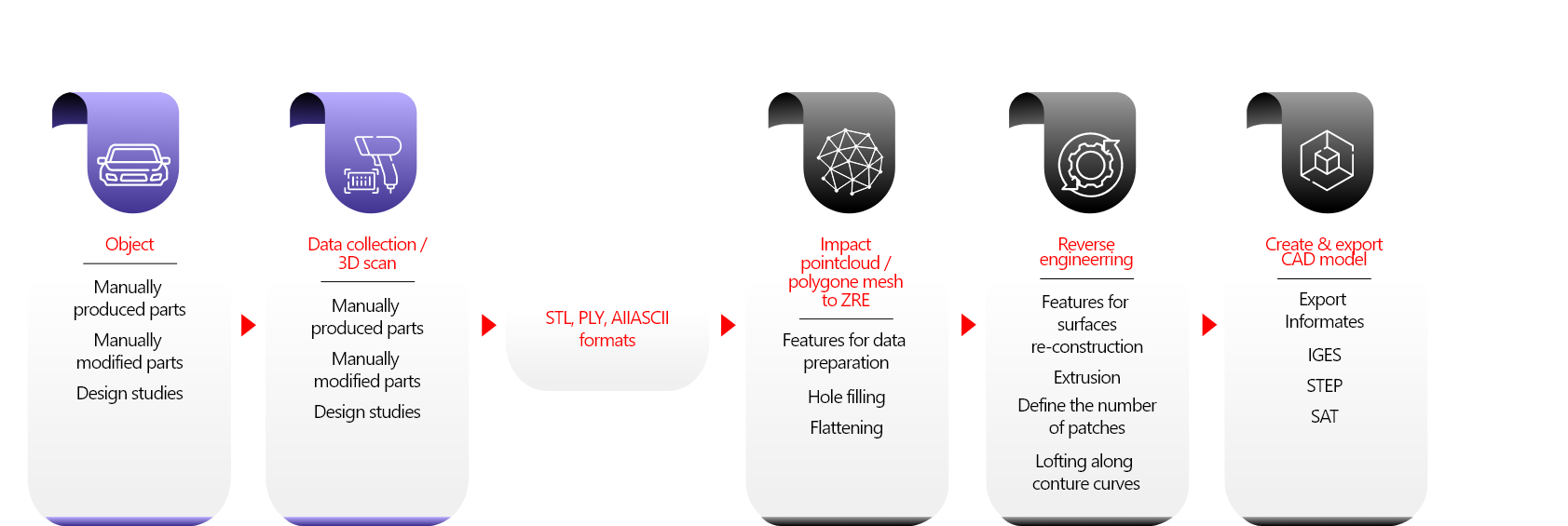

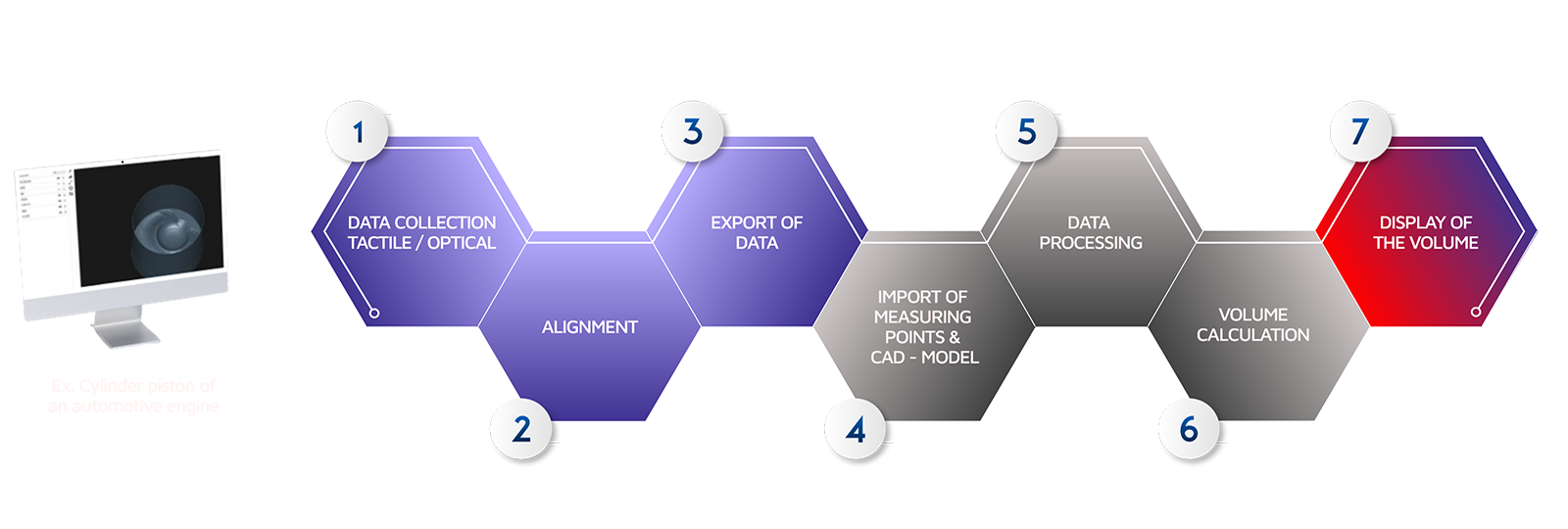

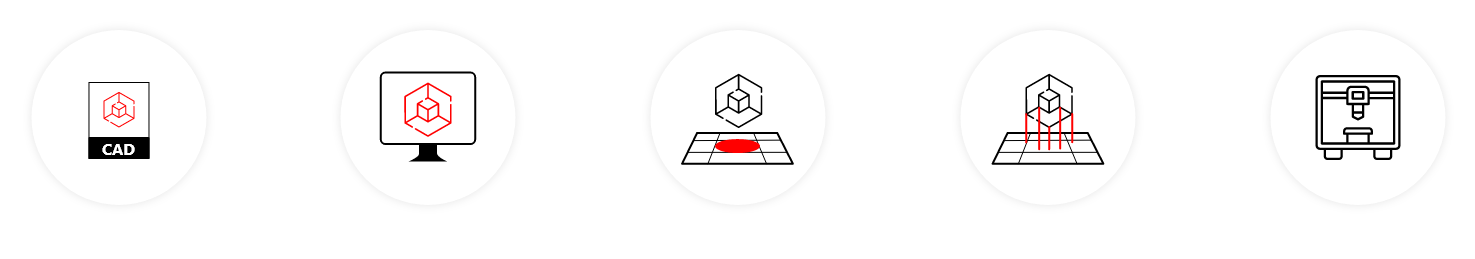

An important step to extract the design data from a finished component (CAD model).

- Begin with scanning the components and importing the point clouds (all ASCII formats) or meshes (STL data) to ZEISS REVERSE ENGINEERING.

- With a variety of function in the ZEISS Reverse Engineering software The point clouds or meshes (STL data) can be processed, in just a few steps a watertight CAD model is created ready to be exported to standard CAD formats.

- High-precision reverse engineering

- Export CAD data to IGES, STEP, SAT

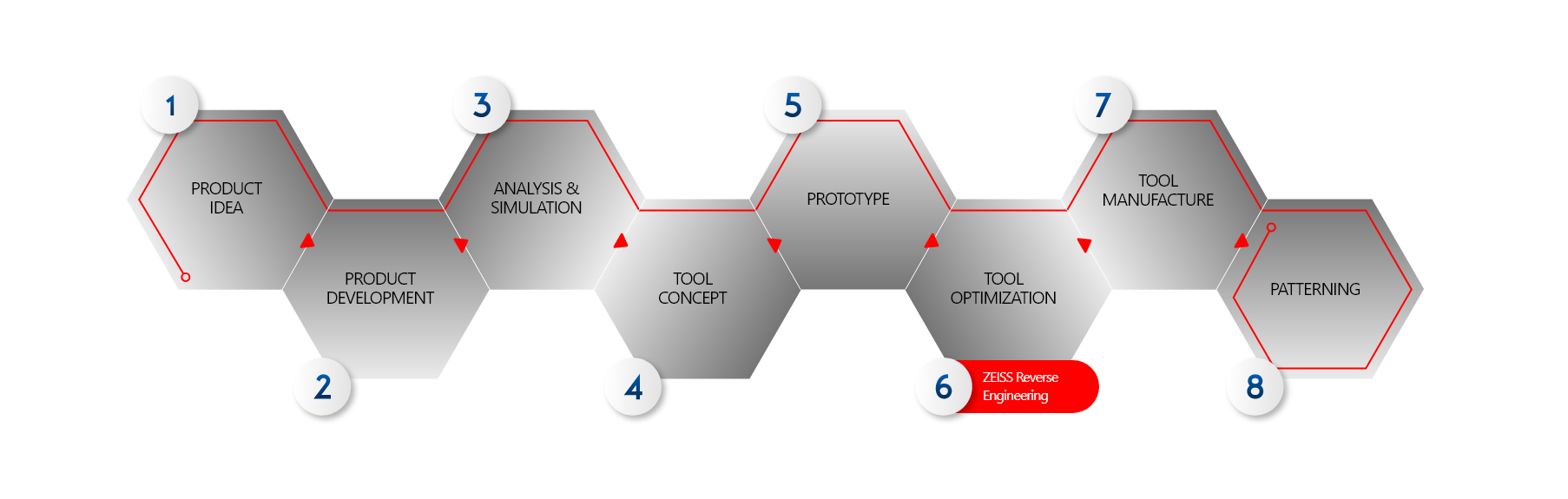

Achieve production-capable tools more quickly and effectively. The integrated tool correction algorithms allow you to lower costs and time-consuming iterations prior to the start of production.

- Makes tool correction incredibly easy.

- Eliminates potential operator errors.

- Correct undercut designs using the “Undercut analysis” function.

- Save at least 50% of the iteration loops in the tool correction process.

- Launch the production process ahead of time.

Achieve production-capable tools more quickly and effectively. The integrated tool correction algorithms allow you to lower costs and time-consuming iterations prior to the start of production.

- Makes tool correction incredibly easy.

- Eliminates potential operator errors.

- Correct undercut designs using the “Undercut analysis” function.

- Save at least 50% of the iteration loops in the tool correction process.

- Launch the production process ahead of time.

-

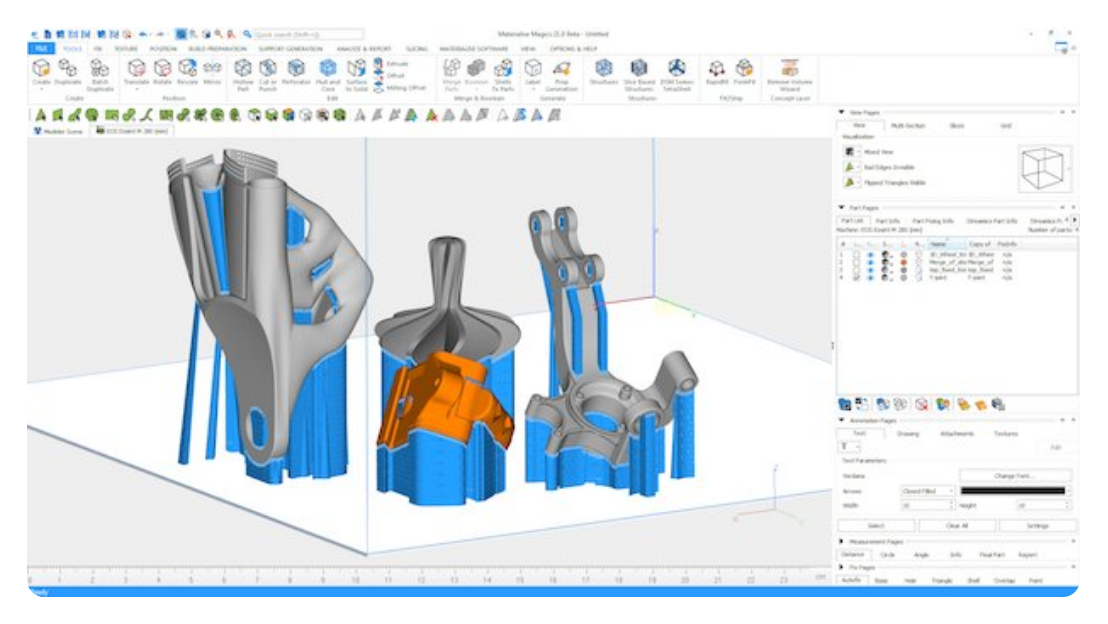

Simulate | Prep | Print

-

An important step to extract the design data from a finished component (CAD model).

- Supports every additive manufacturing (AM) workflow step, from design to post-processing.

- Prepares designs for AM to achieve successful, quality 3D prints.

- Optimizes design structure with lighter weights and enhanced functional properties.

- Streamlines preparation and optimization processes for shorter lead times.

- Reduces print time, material consumption, and post-processing.

- Streamlines time to print with a single, easy-to-use interface.

- Facilitates file preparation with native CAD import.

- Enhances manufacturing efficiency with finely-tuned supports.

- Increases productivity with auto placement.

- Accurately estimates material usage and print time.

- Streamlines time to print with a single, easy-to-use interface.

- Facilitates file preparation with native CAD import.

- Enhances manufacturing efficiency with finely-tuned supports.

- Increases productivity with auto placement.

- Accurately estimates material usage and print time.

-

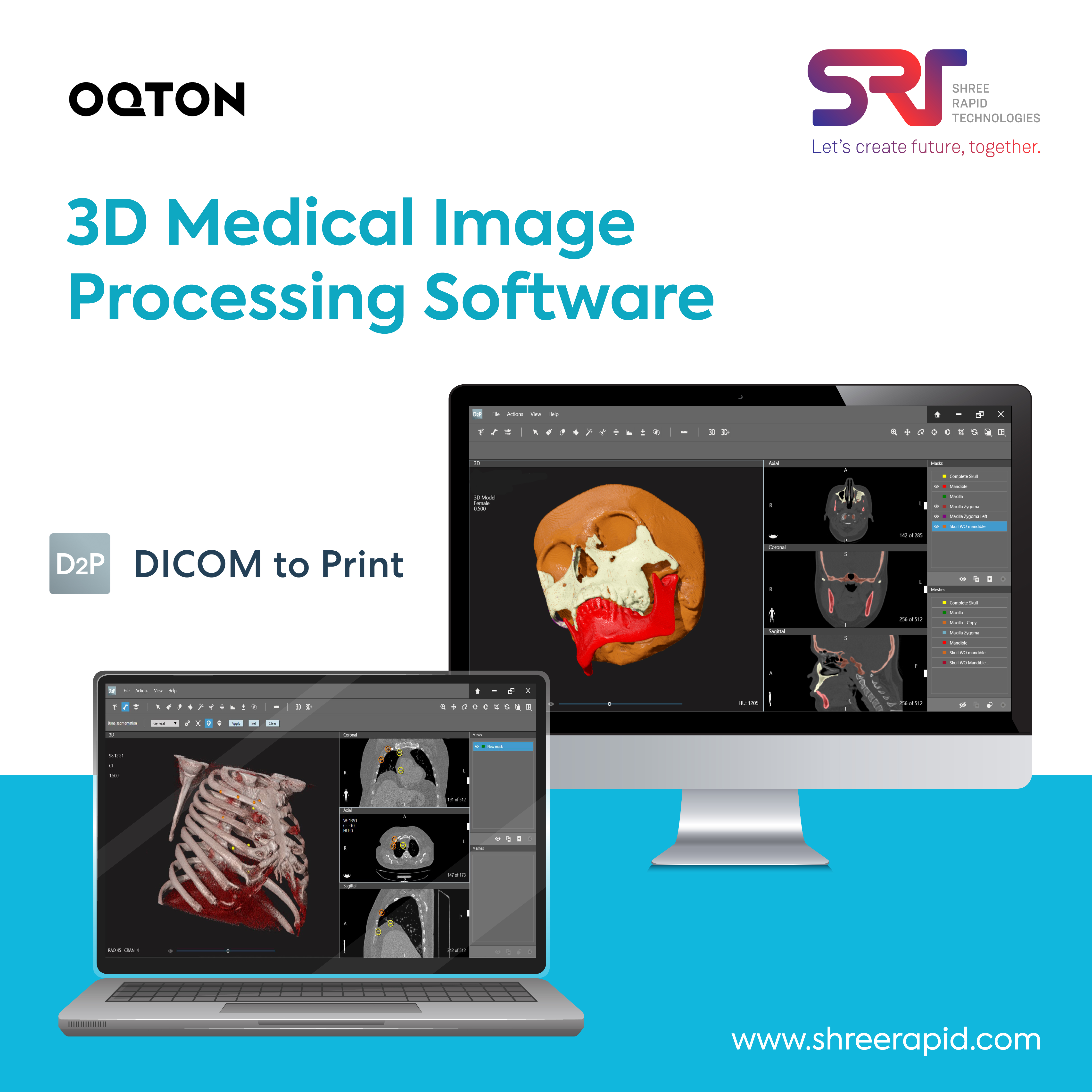

Healthcare

-

- Supports all model preparation steps and various imaging modalities, 3D file formats and 3D Printers.

- Creates 3D models in minutes using automatic segmentation tools.

- Enable pre-operative surgical planning and patient consent.

- Overlays results on patient scan to ensure precision.

- Provides intuitive editing tools and enhanced 3D visualization.