Healthcare.

Material Innovations Expands Production Applications.

The medical industry has very stringent quality, safety requirements & standards, and one of the ways in which the medical industry has been improved and enhanced is through the use of 3D printing technology.

3D printing in healthcare makes it possible for medical professionals to provide patients with a new form of treatment in multiple ways. It is used for the development of new surgical cutting and drill guides, prosthetics as well as the creation of patient-specific replicas of bones, organs, and blood vessels.

Recent advances of 3D printing in healthcare have led to lighter, stronger and safer products, reduced lead times and low costs. Custom parts can be tailored to each individual. This improves the understanding between patients & medical professionals and boosts patient comfort level by allowing interaction with products that are designed especially for their anatomy.

Due to the individualized nature of healthcare, 3D printing is a perfect solution for this industry. 3D printing empowers the creation of prosthetic and orthotic devices custom fitted to a patient’s particular anatomy enhancing their adequacy.

3D printing enables accuracy of the custom parts that can be designed and sent to print in very little time. Within a matter of hours, it is possible to iterate the design of a medical tool based on direct feedback from the surgeon. The fast feedback loop accelerates design development. Manufacturers can also use early 3D printed parts to support clinical trials or early commercialization while the final design is still being optimized.

3D printing has enabled doctors to make several iterations before it is printed, helping them to identify any potential errors, ensuring that the final product is perfect. Costly tooling or machining processes are no longer needed and waste creation is also reduced.

3D printers are now able to produce complex, organic shapes, and the designs are potentially limitless. New composites and hybrid plastics make it possible to create body parts that have improved strength and are lightweight. Through selecting the correct materials and combining them with designs that are completely accurate and precise, the patients benefit from an enhanced quality, comfort and freedom.

While the focus has been on 3D printing implants and medical devices used by patients, one of the largest areas of application is the fabrication of anatomical replicas. Doctors are currently utilizing models produced by 3D printing from patient scan data to enhance the diagnosis of illnesses, clarify treatment decisions, plan, and, even practice chosen surgical interventions in advance of the actual treatments.

High-value healthcare applications..

Patient-Matched Devices.

Medical Device Manufacturing.

Metal Structural Components.

Functional prototypes.

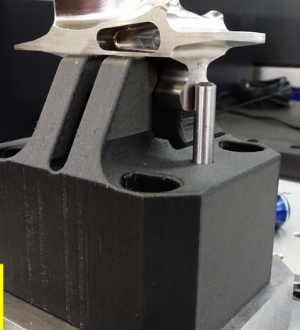

Conformal tooling.

Custom prosthetics and orthotics.

Brackets, harnesses, and sensor mounts.

Assembly fixtures.

Lightweight parts.

Mass Customization.

Surgical Planning Models.

Injection- molded surgical & medical devices.

Insoles & orthotics.

Saving a newborn with the

support of 3D Printing. .

Jaw Reconstruction and 3D Planning for Orthognathic Surgery .

Siemens Energy

Innovation Center .

High Precision Vertical Stacked

Printing for Orthodontic Models .

LightForce Orthodontics gets products to their patients faster .

3D-printed bionic orthoses: Patient-individual pieces with customized & skin-compatible colors .

Saving a newborn with the

support of 3D Printing .

Jaw Reconstruction and 3D Planning for Orthognathic Surgery .

Siemens Energy

Innovation Center .

High Precision Vertical Stacked

Printing for Orthodontic Models .

LightForce Orthodontics gets products to their patients faster .