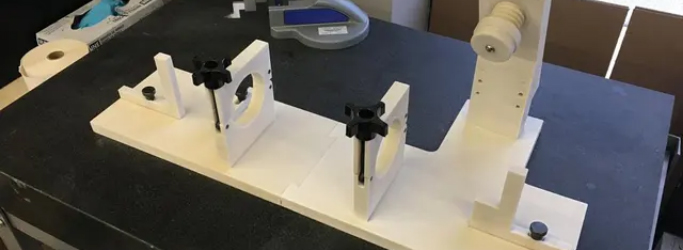

Jigs & fixtures.

Material Innovations Expands Production Applications.

Jigs and fixtures are a manufacturing staples evolving through additive manufacturing to be more readily available, cost-effective and performance-oriented. 3D printing allows engineers to produce jigs and fixtures with boundless complexity to support complex shapes and parts with fine details.

The use of 3D printing for jigs and fixtures enables

- Faster development and/or production cycles

- Reduced investments in time, cost and materials

- Improved functionality for workflow and workforce

- Enhanced self-sufficiency to own processes and outcomes

3D printing offers more than a new methodology for producing accurate and high-quality parts for production support: 3D printing enables new design strategies for optimized parts that can reduce machine wear and tear, enhance worker safety, streamline production workflows, and save considerable time and money.

3D printing allows engineers to produce jigs and fixtures with boundless complexity to support complex shapes and parts with fine details.

Manufacturing, especially mass production, requires a balance of speed and quality. Jigs and fixtures help reduce the cost of manufacturing, increase productivity, ensure precision and repeatability of assembly processes, reduce waste and increase worker safety.

With 3D printing, jigs and fixtures can be produced more efficiently and effectively than with welding or machining, and depending on volume, with traditional plastic injection molding as well. This efficiency helps to reduce manufacturing costs and lead times and improve manufacturing and assembly line capacity, speed and responsiveness.

3D printing jigs and fixtures introduces three main benefits to the manufacturing process: better speed, cost savings and increased functionality with new design capabilities.

Speed.

3D printed jigs and fixtures can be printed in as little as a few hours versus the days it may take to produce jigs and fixtures through traditional methods. This can shorten the supply chain, and provide immediate access to the tools needed.

Cost.

By eliminating investments in tooling, the cost of jigs/fixtures can be lowered. 3D printing can also be used for design iteration of jig/fixture prototypes before the final design is identified.

Functionality.

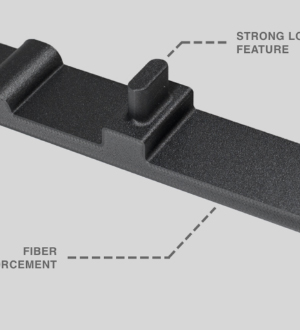

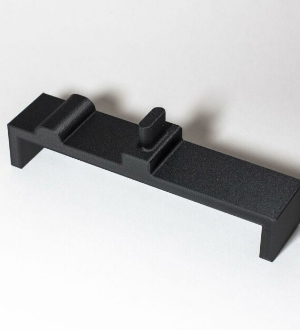

3D printing enables increased complexity and customization that opens new design capabilities for creating jigs/ fixtures with geometries that may be impossible to machine.

How do 3D printers build better jigs and fixtures?.

Small features that would be difficult to machine

Consolidating multiple parts into a single build.

Complex geometries considered impossible to machine due to tool clearance in milling or turning

Increasing rigidity within the design phase.

Engravings that are integrated into the product design rather than added as a separate step

Accelerated access to replacement parts.

Common jigs and fixtures 3D printers can produce.

3D printers can accurately print a range of jigs and fixtures, and are ideal for producing:

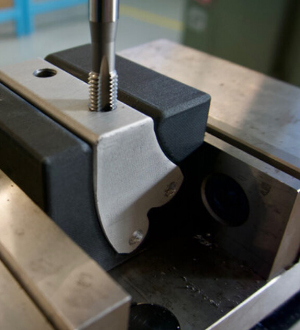

Drill guides, which keep drill bits in place while in use.

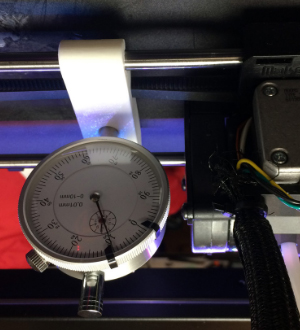

Gauges to confirm a go/no-go decision.

Assembly and disassembly jigs.

Bonding jigs.

Vise and clamp inserts.

Masking templates.

Table-top mounting plates.

Press fit applications.

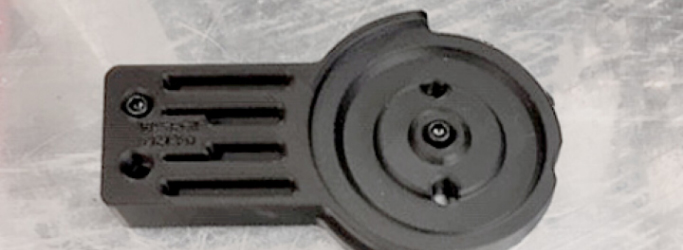

Custom part carriers and poka-yoke tools.

Welding and soldering fixtures.

SMT masks and assembly.

Fastener-driving assemblies.

G-NG gauges.

3D Printed Jigs and Fixtures at Renault Sport Formula One .

Production Time, Cost for TIG Welding Fixtures Reduced with SLS 3D Printings .

The ProJet MJP 3D Printer Saves Citizen Watch Time and Money .

Columbia Elektronik AB:

Onyx ESD Testing Fixtures .

Dana Incorporated:

CMM Fixtures .