Projection Micro Stereolithography (PµSL).

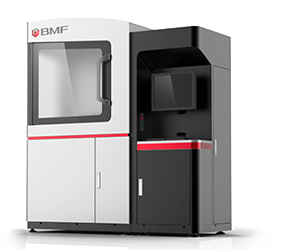

2μm Series Printers.

Properties

The 2μm series is our highest resolution system, perfect for applications that require ultra-high resolution and tight tolerances.

Highlights

Customizable high-resolution optical system and movement platform (with resolution down to 2μm).

Step-and-repeat process that allows for achievement of both high resolution and large area.

Controlled processing technology to produce highly precise 3D printed objects.

Real-time image monitoring, auto focus, and exposure compensation.

Operation software with microArch graphic interface system and customer parameter setting.

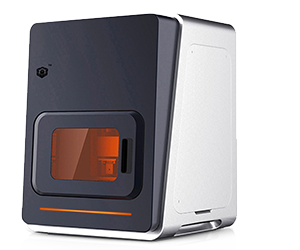

10μm Series 3D Printers.

Properties

The 10μm series 3D printer is the ideal solution for businesses and universities requiring ultra-high resolution, accuracy, and precision in a desktop package.

Highlights

Within the 10μm series, the S240 3D printer is the industrial workhorse, with the ability to print with engineering-grade materials and a larger build volume – specifically designed to meet the needs of industrial production.

BMF’s 10µm series 3D printers offer a level of precision and accuracy that delivers the most challenging micro parts at production quality.

Customizable high-resolution optical system and movement platform (with resolution down to 10μm)

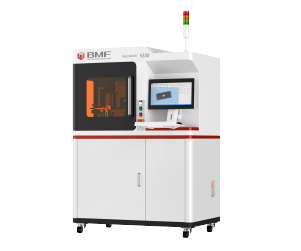

25μm Series Printers.

Properties

the microArch S350 is a 25μm platform which can be used not only for printing micro-scale parts with high-resolution features, but also for a broader range of small parts requiring high accuracy or precision.

Highlights

Automated lateral membrane shift - enables automated part removal with option for robotic integration

Auto resin adjustment with resin cassette

Laser displacement sensor

Advanced roller system spreads layers in seconds

Larger DLP chip --> 6 projection zones – resulting in faster printing speedsMaterials offered for PµSL..

- Materials.

-

HTL.

HTL is a high performance engineering material with high strength, rigidity, and heat resistance, able to withstand temperatures up to 114°C.

UTL.

UTL offers high toughness and elongation for high flexibility applications.

BIO.

BIO is a biocompatible resin suitable for non-implantable medical applications. BIO can undergo sterilization and has passed numerous ISO biocompatibility tests.

RG.

RG from the Forward AM Ultracur3D® photopolymer resin line is a durable engineering material which can be used to print functional end-use parts. In addition to being biocompatible, it doesn’t uptake any water and is suitable for a wide range of applications such as electrical cases, medical devices, snappers and functional prototyping. Only available on the microArch 200 series.

HT 200.

HT 200 is a high temperature material that can withstand temperatures up to 200°C with high strength and durability, perfect for end use applications.

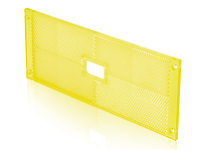

AL Ceramic.

AL (Alumina) Ceramic is perfect for applications involving tooling, casings and housings, and medical devices – able to withstand high temperatures with high strength properties and chemical resistance. Only available on the microArch 200 series.

TOUGH.

TOUGH is a rigid, robust engineering material with a good combination of strength and elongation. TOUGH can be used to produce end-use parts.

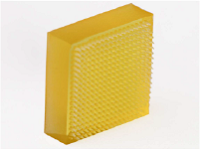

BMF MED.

BMF MED powered by 3D Systems is a rigid amber material for applications requiring biocompatibility, translucency and/or thermal resistance. It provides parts with crisp details, that can be sterilized and tested at high temperatures, over 100 °C.

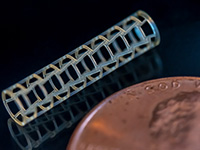

Projection Micro Stereolithography (PµSL).

Boston Micro Fabrication (BMF) is the leading manufacturer of industrial micro precision 3D printers. BMF uses an innovative technology called Projection Micro Stereolithography or PµSL, a technique that allows for rapid photopolymerization of a layer of liquid polymer using a flash of UV light at micro-scale resolution.

Using industrial-grade composite polymers and ceramics, BMF is capable of achieving resolution of 2µm~50µm and tolerance of +/- 5µm~25µm, thus providing mold-free, ultra-high-resolution fast prototyping and end part capability. Today, BMF is the only industrial 3D printing company to match the quality of high-resolution injection molding and CNC processing.

Applications:

- Medical Devices

- Electronics

- Microfluidics

- Micro-Electromechanical Systems (MEMS)

- Biopharma

- Education/ Research